In Greek mythology, Zeus punished Sisyphus for cheating death by forcing him to roll a huge boulder uphill for eternity. I suspect Apple’s operations teams feels similarly cursed. Not only have they had to adapt to the pandemic, but they had to mitigate the effect of Russia’s invasion of Ukraine and must now do what they can to salvage affairs as the situation in Taiwan decays, which could be an existential threat to the company and its business.

The incredible uphill journey

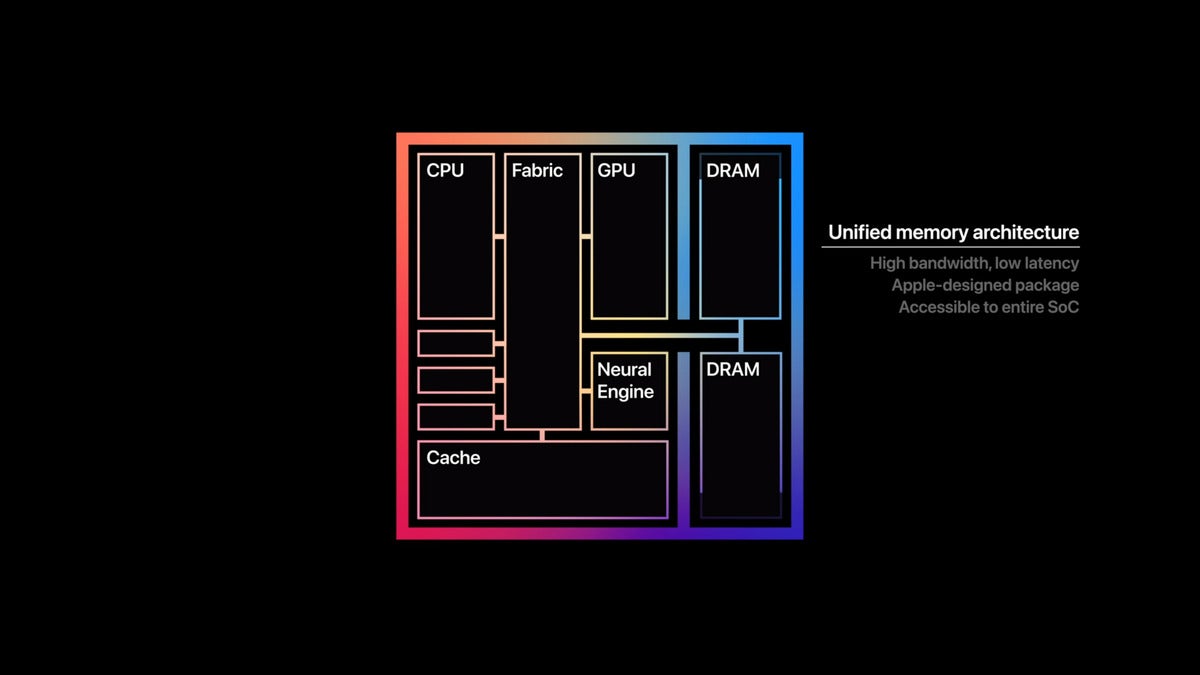

It’s not just Apple, of course — the entire tech industry stands threatened by tension between Taiwan and China. Apple Silicon chips used across its product range are made by Taiwan’s own TSMC. TSMC Chairman Mark Liu recently warned that any further tension in Taiwan would generate big problems.

Liu also noted the sophistication of the tech industry supply chain, telling CNN: “Because this is such a sophisticated manufacturing facility, it depends on real-time connection with the outside world, with Europe, with Japan, with US, from materials to chemicals to spare parts to engineering software and diagnosis.”

When it comes to manufacturing, the importance of China to the Apple supply chain was really bought home when COVID-related lockdowns meant Apple couldn’t make enough Macs or iPads to meet demand. In that context, it seems counterintuitive that Apple this week told corporate staff that they no longer need to wear masks to protect against COVID-19.

A risk to assumptions?

I imagine the ops teams take courage that their ability to manage and execute Apple’s business in challenging market conditions still enabled the company to achieve record results in its last quarter, and to anticipate growth into the September quarter. All the same, Apple CFO Luca Maestri was perhaps more realistic than he’d hoped to be when he warned:

“Given the continued uncertainty around the world in the near term, we’re not providing revenue guidance, but we are sharing some directional insights based on the assumption that the macroeconomic outlook and COVID related impacts to our business do not worsen from what we are projecting today for the current quarter.”

The company must be praying relations between China and Taiwan don’t deteriorate more. Such an outcome would devastate product manufacturing and would create terrible turmoil. FBI Director Christopher Wray recently warned that conflict between the two nations would “represent one of the most horrific business disruptions the world has ever seen.”

Can we diversify fast enough?

Apple is doing what it can to build a more resilient supply chain, but it’s an uphill journey. Digitimes suggests it is urging suppliers to set up manufacturing facilities in Vietnam and to diversify production across multiple factories. The company is also portioning out production of some of products among additional suppliers to help build resilience.

TSMC is expected to open a $12 billion Apple Silicon production facility in Arizona, with assistance under the at-last passed Chips and Science Act. But even this won’t be operative for at least a year. In most cases, Apple (and everyone other than Apple) is not yet able to diversify production outside China, even if there were enough coders and engineers in those markets to staff these machines.

All the same, the huge demand for Apple’s products means that even as factories in India, Vietnam and (perhaps) Brazil and Mexico switch on the lights, they still can’t scale to meet all that demand. (Pegatron’s latest factory in Mexico won’t be online until the end of 2023, according to local media reports.)

This is of particular importance as Apple allegedly prepares to introduce what it surely hopes will become its next "pillar" product, AR Glasses, probably next year. It’s reasonable to think that if those products do appear, Apple will still be reliant on manufacturing from across that region, generating yet more headaches for that hard-working operations team.

Please follow me on Twitter, or join me in the AppleHolic’s bar & grill and Apple Discussions groups on MeWe.